Email Us

Why HRC55° and HRC65° Cutting Tools Matter for Precision Machining

When it comes to precision cutting tools, hardness is a critical factor. At Saikeiny Tools, we provide a full range of HRC55° and HRC65° carbide end mills and coated cutting tools designed to match your machining challenges.

Understanding the difference between HRC55 and HRC65 helps you choose the most cost-effective and performance-driven tool for your job.

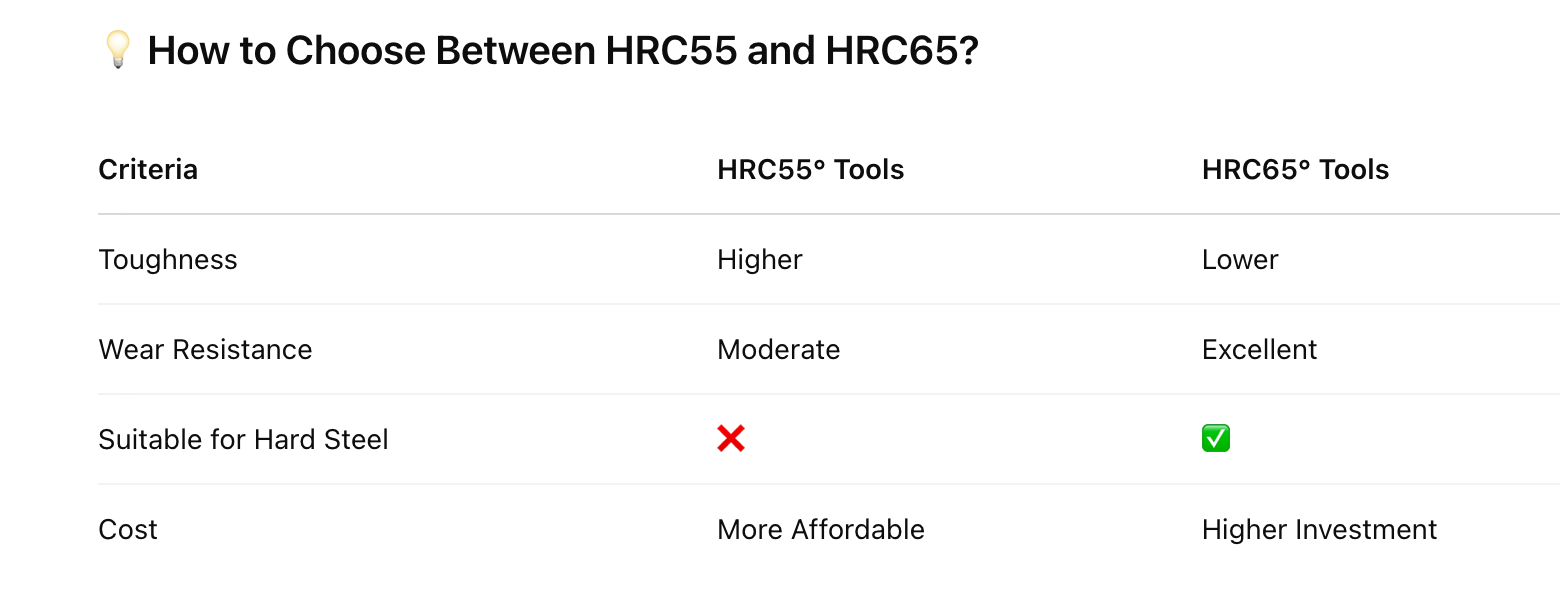

What Does HRC Mean?

HRC stands for Rockwell Hardness Scale C, which measures the hardness of materials. The higher the HRC rating, the harder (and usually more wear-resistant) the cutting tool is.

HRC55° Cutting Tools: Balanced for General Use

Saikeiny’s HRC55° series is engineered for general-purpose machining across various materials.

Key Benefits:

- Suitable for mild steel, carbon steel, and aluminum alloys

- Balanced toughness and hardness

- Ideal for medium-speed cutting

- More cost-effective than higher-HRC tools

Recommended for: Job shops, light-duty machining, aluminum processing

Available in: Nano Blue Coating, 2/3/4 flute end mills, ball nose, and chamfer cutters

HRC65° Cutting Tools: Built for High-Performance Needs

Saikeiny’s HRC65° tools are designed for demanding environments and hardened materials.

Key Benefits:

- Optimized for high-speed cutting

- Excellent wear and heat resistance

- Longer tool life, especially in tool steels, cast iron, and heat-treated parts

Available in: TiAlN/Nano Blue Coating, corner radius cutters, ball nose, 4-flute end mills

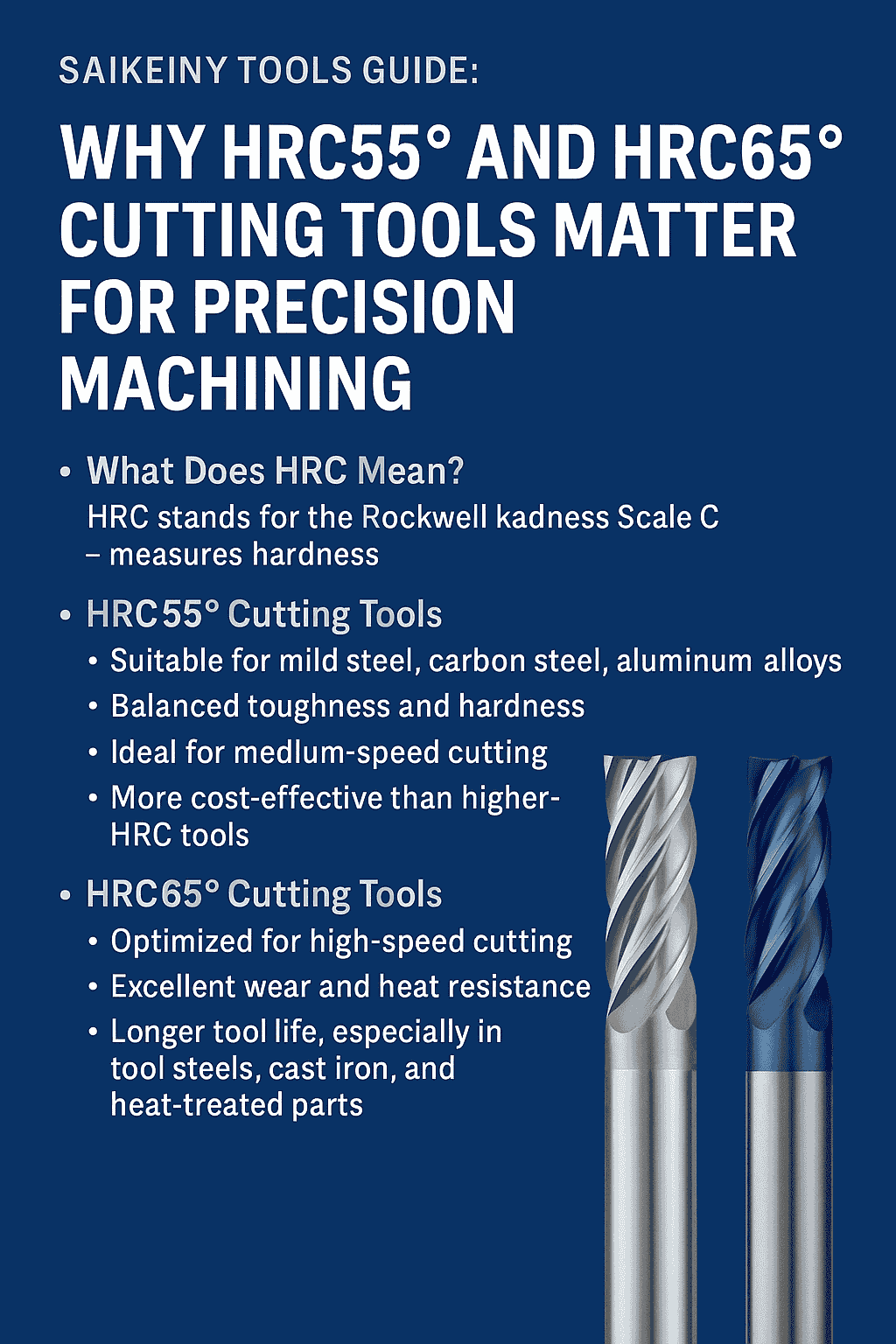

How to Choose Between HRC55 and HRC65?

Saikeiny Tools recommends using HRC55° for general use, and upgrading to HRC65° when precision, speed, or wear resistance are required.

Choose Saikeiny Tools for the Right Hardness

At Saikeiny Tools, we offer customized solutions based on your material, spindle speed, and production goals. Whether you're cutting aluminum or hardened steel, we help you select the right hardness level and coating for best results.

👉 Explore our full range of HRC55° and HRC65° cutting tools at www.saikeinytools.com or contact our team for expert advice.

- What Is a Thread Die – And How to Use It for External Threading?

- Coating Guide: TiN vs. TiAlN vs. Nano Blue – Which Coating Fits Your Cutting Tool Needs?

- What is a drill bit?

- Our Esteemed Partners in Industrial Tooling Excellence

- Threading 101: Understanding Taps and How to Choose the Right One for Your Machining Needs

- Happy Lunar New Year

About Us

Contact Us

Area B, Tool and Measuring Instrument Trading Center, Wenling City, Zhejiang Province, China 317599

Copyright © 2025 Saikeiny Tools Co., Ltd. All Rights Reserved.